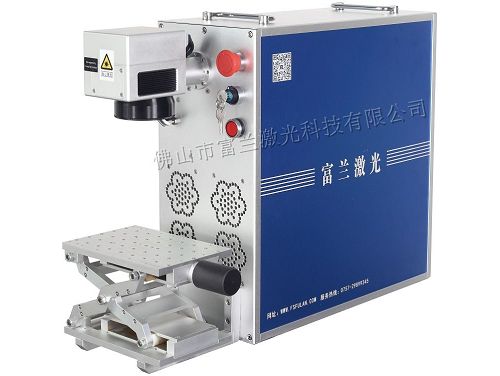

Foshan Fulan Laser Technology Co., Ltd.

National Hotline: 0757-29899345

Manager Wen: 18902563402

Fax: 0757-29899345

Business QQ: 2801827697

E-mail: china@fsfulan.com

Address: No.14, Leliu Port Intensive Industrial Zone, Shunde District, Foshan CityThe high-tech zone almond altar town, shunde, foshan city shun industry west road no. 15 cimc valley 20 9 / f, building B

If you have a little understanding of laser marking machines, you will know that fiber optic machines have the longest service life of all light source types, which can be as long as 100,000 hours. 100000 hours, what is this concept? ! If you work for 8 hours a day, it can be used for nearly 34 years. When the service life is reached, you can continue to use it only by replacing the laser.

There is no discrimination without comparison, so do you know the service life of other types of laser marking machines? Foshan Fulan Laser will tell you: the life of semiconductor laser marking machines is about 6 years; CO2 laser marking machine: metal tube It can be used for 5 to 10 years, and the glass tube can be used for 3 to 9 months; the green laser marking machine can be used for 2 to 5 years; the ultraviolet laser marking machine can be used for 3 to 10 years.

Why is the service life of fiber laser marking machine so long?

This is determined by the performance advantages of the fiber laser itself. Fiber laser has high electro-optical conversion efficiency, which can greatly save power consumption, reduce operating costs, and achieve the highest production efficiency. Its working material is crystal, which can support long-term excitation. The laser oscillates in the fiber and produces less heat. It needs air cooling, no need to equip a chiller, and does not need to change the working gas from time to time like a gas laser, less consumables... Based on these factors, coupled with the correct maintenance method, the fiber laser marking machine has a long working life.

Below, the laser equipment manufacturer (Foshan Fulan Laser Technology Co., Ltd.) tells you how to maintain the fiber laser marking machine:

1. Operate strictly in accordance with the startup steps of the equipment, and do not operate randomly;

2. Be careful when moving to avoid damage to the parts of the equipment due to improper movement;

3. Regularly clean equipment (fans, workbench machines);

4. After the equipment is shut down for half an hour, put on the cover of the field lens and clean up the objects and residues on the work surface;

5. In operation, once a fault is found, it must be stopped immediately to avoid accidents;

6. When the equipment is not working, the power supply should be cut off;

7. During the working process of the marking machine, do not move the marking machine to avoid damage to the machine;

8. Do not cover and stack other items on the marking machine to avoid affecting the heat dissipation effect of the machine;

9. The working environment of the equipment must be kept dry, ventilated, clean, smoke-free and dust-free, the temperature should be kept at 15-30℃, and the humidity should be 45-75%;

10. The fluctuation of the power supply grid should be less than 10%. If it cannot be guaranteed, a voltage stabilizer must be installed;

11. Please don't turn on and off frequently, and it can be turned on at least 3 minutes after turning off.