Foshan Fulan Laser Technology Co., Ltd.

National Hotline: 0757-29899345

Manager Wen: 18902563402

Fax: 0757-29899345

Business QQ: 2801827697

E-mail: china@fsfulan.com

Address: No.14, Leliu Port Intensive Industrial Zone, Shunde District, Foshan CityThe high-tech zone almond altar town, shunde, foshan city shun industry west road no. 15 cimc valley 20 9 / f, building B

The rotating stator is the collective name of the rotor and the stator, and is a component of the motor. The main function is to be cut by the magnetic lines of force in the rotating magnetic field to generate (output) current. The fixed part is called the stator, and its main function is to generate a rotating magnetic field.

Since its development, there are more and more specifications of the stator and rotor, most of the specifications are very similar, so it is easy to cause mixing. Since the rotor and stator are generally laminated with multiple 0.5mm silicon steel sheets, one more iron core or one less iron core is difficult to distinguish with the naked eye. Therefore, once the materials are mixed, they must be compared or measured one by one. Count the number of iron chips one by one to distinguish them. The emergence of laser marking machines and the maturity of laser marking technology have solved this big problem for rotor and stator manufacturers.

The principle of the laser marking machine is that the laser emitted by the laser undergoes a series of treatments. After the lens is focused, the energy is concentrated in a small range, so that the surface material is instantly melted or even vaporized. By controlling the laser on the surface of the material Path to form the required graphic mark. According to different material properties (such as melting point, boiling point, temperature at which chemical change occurs), the workpiece will undergo a series of physical or chemical changes, such as melting, gasification, oxide formation, discoloration, and so on.

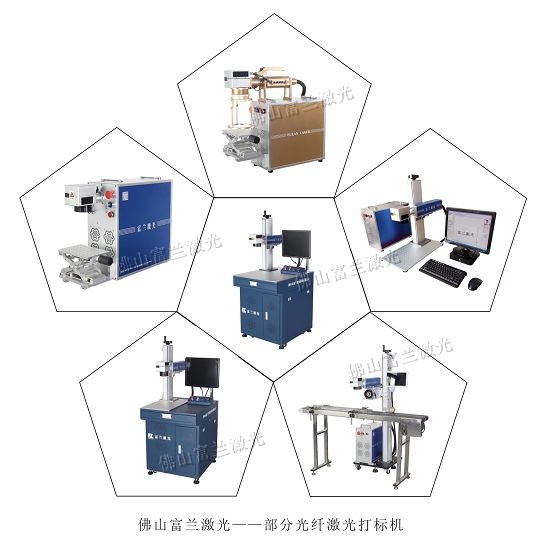

The material of the rotor and stator is metal, and the metal material used is a fiber laser marking machine. The fiber laser marking machine produced by Foshan Fulan Laser Technology Co., Ltd. has the following characteristics:

1. The beam quality is good, close to the diffraction limit, which can realize more precise marking;

2. Using optical fiber output, equipped with high-speed digital scanning head, marking speed is 2-3 times that of traditional models;

3. The electro-optical conversion rate is as high as 30%, and the power consumption is about 10% of that of traditional models;

4. Cooled by air cooling, the whole machine is compact;

5. No consumables, maintenance-free, and long service life.

The mark marked by the laser marking machine has the characteristics of high precision, clarity, smooth and burr-free marking and permanent, and will not fade due to environmental relations, touch, acid and alkaline gases, high temperature, low temperature, etc. Therefore, rotor and stator manufacturers can use laser marking machines to mark specifications, models, batches, logos, and other information on products, which is convenient for product management, effectively avoids mixing, and can protect and improve their own brand.

Advantages of laser marking:

1. Marking is permanent: the laser marking mark is not easy to imitate and change, and the mark will not fade due to environmental relations.

2. Non-contact processing: the workpiece will not produce internal stress after marking, ensuring the original accuracy of the workpiece. No corrosion to the working surface, no "tool" wear, no poison, no pollution.

3. High marking precision: The thinnest line width of the UV laser marking machine produced by Foshan Fulan Laser can reach 0.01mm, and the marking is fine, clear, durable, beautiful and good in hand.

4. Wide application range: suitable for marking a variety of materials.

5. Low operating cost: The laser marking machine can mark in one step, with fast marking speed and low energy consumption, without consumables.

6. High working efficiency: The laser marking machine is controlled by an industrial computer. The laser beam under computer control can move at a high speed, and the marking can be completed within a few seconds.

7. Fast editing and development speed: any content can be marked and edited at will. The combination of laser technology and computer technology, all the information to be marked is edited in real time by the computer, and laser printing output can be realized by editing on the computer. And can change the content of marking design manuscript at any time. No mold opening or plate making is required, marking immediately

8. Flexible configuration: it can be statically marked to meet commercial small batch or single processing requirements; it can also be dynamically marked to meet the requirements of industrialized assembly lines for mass production.

9. Consistent effect: Ensure that the processing effect of different batches of the same product is completely consistent.

10. High degree of automation: It can be used in conjunction with the production line to realize automatic feeding, automatic identification and positioning, and automatic marking. (PS: The standard machine does not have the functions of positioning, automatic focusing, automatic identification and marking, automatic material conveying, etc., all require manual operation, low automation and low efficiency. Foshan Fulan Laser has a professional R&D team, which can be A non-standard equipment tailored to customer needs.)