Foshan Fulan Laser Technology Co., Ltd.

National Hotline: 0757-29899345

Manager Wen: 18902563402

Fax: 0757-29899345

Business QQ: 2801827697

E-mail: china@fsfulan.com

Address: No.14, Leliu Port Intensive Industrial Zone, Shunde District, Foshan CityThe high-tech zone almond altar town, shunde, foshan city shun industry west road no. 15 cimc valley 20 9 / f, building B

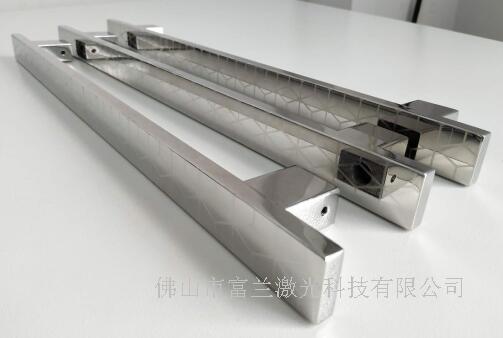

Living in this era of fighting beauty, people are pursuing beauty, and products are also pursuing beauty, starting with beauty, getting stuck in effects, and loyal to quality. If a product's beauty is not enough, the configuration and functions are similar. In the qualitative market, it will soon be buried, and there is no talk of being "trapped in effect" or "loyal to quality". A good appearance is a powerful tool to capture customers' attention. No matter how exquisite the door or drawer is, as long as the handle is not exquisite enough, it will reduce the overall appearance. Therefore, as an indispensable part of home cabinets, doors and drawers, the handle is very decorative. The laser marking machine can make an ordinary handle (also called handle, handle) extremely delicate.

Laser marking machine, also known as laser engraving machine, laser machine, laser engraving machine, etc., uses high-energy density laser to locally irradiate the switch panel to vaporize the surface material of the product or change the color of the chemical A marking method that reacts, leaving a permanent mark. Laser marking has a permanent feature, so there is no need to worry that the markings on the handle will become blurred due to excessive touch or time.

Below, the editor of Fulan Laser will talk about the advantages of using laser marking machine to handle the handle:

1. Non-contact processing, no need to touch the surface of the product, the workpiece will not generate internal stress after marking, and the original accuracy of the workpiece is guaranteed. No corrosion to the surface of the workpiece, no "tool" wear, no poison, no pollution;

2. Environmental protection: no consumables, no harmful substances to the environment and human body, no pollution, in line with GB7247-87; GB10320-88 standards. However, some materials will produce smoke when laser marking, generally use the smoke exhaust system to deal with;

3. Fast speed: The laser marking machine is controlled by an industrial computer. The laser beam under computer control can move at a high speed, and the marking process can be completed within a few seconds;

4. Low cost: Laser marking is formed at one time, with low energy consumption and no consumables;

5. The mark is permanent: laser marking is essentially a "destructive removal" process. The marked mark is not easy to imitate and change, and the mark will not be affected by environmental factors (touch, acidic and alkaline gas, high temperature , Low temperature, etc.) and subside;

6. High marking accuracy: The article marked by laser marking machine has fine patterns, fine and clear, beautiful and good hand feeling, the surface of the lettering is smooth, natural and textured; the minimum line width can reach 0.01mm;

7. Wide application range: the same machine is suitable for marking multiple materials;

8. Fast editing and development: both marking and marking are required. Any content can be marked and can be edited at will. The combination of laser technology and computer technology, all the information to be marked is edited in real time by the computer, and the laser print output can be realized by editing on the computer, and the marking design can be changed at any time Manuscript content. Such as: patterns, text, characters, batch numbers, dates, barcodes, QR codes, etc.;

9. Flexible configuration: it can meet commercial small batch or single processing requirements, and can also meet the requirements of industrialized assembly line mass production;

10. Consistent effect: ensure that the processing effect of different batches of the same product is completely consistent;

11. Simple operation: no experience is required, Foshan Fulan Laser will conduct professional one-on-one training operations for customers until the customer's operators can operate the equipment correctly and proficiently, which can generally be learned within 2 hours;

12. High degree of automation: using computer integrated intelligent operation, it can realize automatic feeding, automatic identification and positioning, automatic marking, etc., and the marking speed is super fast; it can work in a static state or in a high-speed flow state of the production line;

13. Stable performance: It can work continuously for 24 hours a day. The maintenance-free time is up to 100,000 hours.

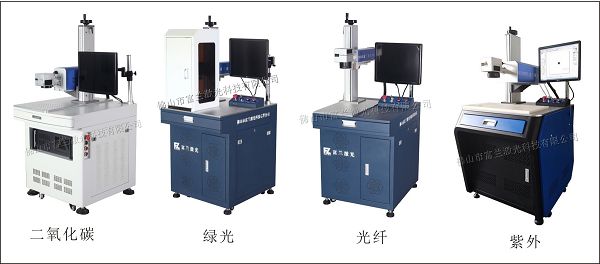

The laser marking machine can engrave on almost any material, but the type of laser marking machine used in different materials will be different. Foshan Fulan Laser is a high-tech enterprise integrating the research and development, production, sales and service of laser equipment. , The products are complete, the quality is excellent, and the service is efficient. Regardless of the material of the handle, Fulan Laser can meet your requirements.