Foshan Fulan Laser Technology Co., Ltd.

National Hotline: 0757-29899345

Manager Wen: 18902563402

Fax: 0757-29899345

Business QQ: 2801827697

E-mail: china@fsfulan.com

Address: No.14, Leliu Port Intensive Industrial Zone, Shunde District, Foshan CityThe high-tech zone almond altar town, shunde, foshan city shun industry west road no. 15 cimc valley 20 9 / f, building B

As the current advanced marking equipment, laser marking machine can improve the efficiency of operation and the quality of products. Because the laser marking machine is small in size, simple to operate, environmentally friendly, long service life, high processing efficiency, strong flexibility, high stability, wide applicability, powerful functions, high precision and permanent marking of the marking. In addition, the price of the equipment has become more and more affordable in recent years, adapting to the needs of production development, and gradually replacing other marking, cutting, lettering, coding, dotting, punching, and burning equipment on the market. It is estimated that many companies or individuals may be planning to purchase laser marking machines. For most first-time buyers, because they don’t know the equipment, they don’t know how to choose the equipment that suits their products. Next, Foshan Fulan Laser will tell you Purchase the three-size and small door of the laser marking machine, hoping to help users in need.

Clever one: Choose laser equipment according to the needs of the product to be processed.

Laser marking equipment can be roughly divided into marking, cutting, coding, dotting, deep engraving, and burning in different ways of use. Some are special machines, and some are all-in-one machines, which should be selected according to the main needs.

Clever two: consider which materials are used for marking.

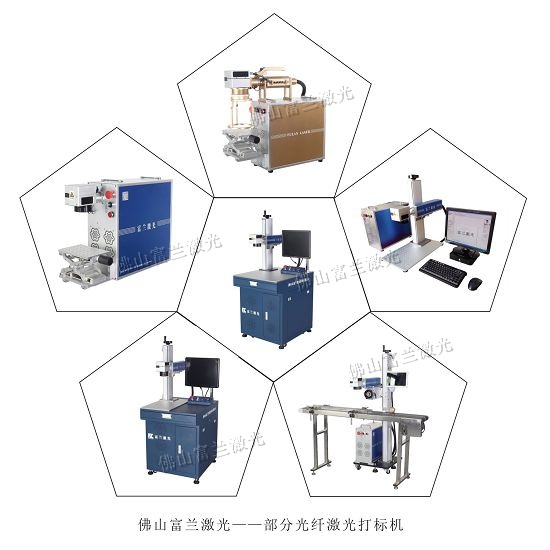

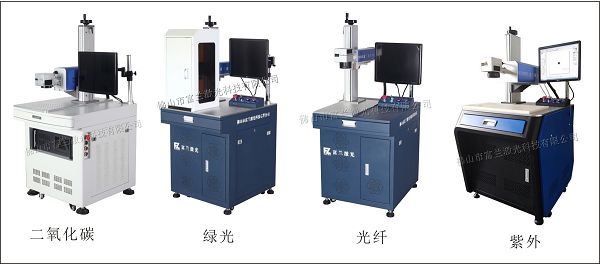

Products of different materials (even products of the same material with different purity or different pre-marking treatment processes) are applicable to different types of laser marking machines. Currently, there are five types of laser marking machines: optical fiber, green light, ultraviolet, CO2 and mopa.

1. Fiber laser marking machine: mainly used for marking with metal materials, but also for marking some non-metal materials. For example: marking stainless steel, iron, copper, magnesium, aluminum, gold, silver, titanium, platinum and other metals and various metal oxides, in addition to marking various high-hard alloys, oxides, electroplating, Coating, ABS, epoxy, etc.

2. Green laser marking machine: mainly used in 3C industry marking, white goods, electrical appliance shell marking, food, medicine production date marking and other materials; metal or non-metal coating removal; various materials Scribing, blind groove processing; new ultra-thin metal foil micro-hole production, etc.

3. Ultraviolet laser marking machine: mainly used in the high-end market of ultra-fine processing. For example: marking of polymer materials and sensitive materials; removal of metal or non-metal coatings; internal carving of glass crystal products; scribing of various materials and blind groove processing; new ultra-thin metal foil micro-hole production, etc. The beam quality is good, the focused spot is smaller, ultra-fine marking can be realized, the heat-affected area is extremely small, no thermal effect, and no material scorching problem.

4. Co2 laser marking machine: mainly used for marking and cutting non-metallic materials, such as: leather, cloth, wood, bamboo products, plastics, rubber, PVC, etc.

5. mopa laser marking machine: mainly used for aluminum alloy, aluminum oxide blackening, aluminum oxide sheet surface stripping, electronics, semiconductors, ITO precision processing, stainless steel color marking, deep carving metals, plastics and other sensitive materials and PVC plastics Marking in the pipe industry.

Clever Three: Choose the appropriate machine format according to the product size to be processed.

Regarding the choice of laser marking format, the larger the machine format, the better. On the one hand, large-format equipment is of course more expensive. On the other hand, the standard laser marking machine has a maximum marking area of only 300*300mm, and the average laser output will be unstable if it exceeds this range, resulting in products on the same table. The marking effect varies in depth (if your marking format is too large, it is recommended that you use the non-standard machine independently developed and produced by Foshan Fulan Laser-large format online laser marking machine, which can complete large format at one time/ Large-area/large-range high-precision marking), so it is correct to choose the appropriate format.

Regardless of whether it is a laser marking machine, a laser online printer, a laser welding machine, a laser deep engraving machine, or other laser equipment, you only need to clearly tell Fulan Laser a few parameters before purchasing the machine, Fulan Laser A professional salesperson will recommend the most suitable laser marking machine for you and provide you with free proofing. If the standard machine cannot meet your requirements, Foshan Fulan Laser has a professional R&D team, and the salesperson will summarize your requirements to the technician, and the technician will tailor a laser marking machine that meets your requirements.