Foshan Fulan Laser Technology Co., Ltd.

National Hotline: 0757-29899345

Manager Wen: 18902563402

Fax: 0757-29899345

Business QQ: 2801827697

E-mail: china@fsfulan.com

Address: No.14, Leliu Port Intensive Industrial Zone, Shunde District, Foshan CityThe high-tech zone almond altar town, shunde, foshan city shun industry west road no. 15 cimc valley 20 9 / f, building B

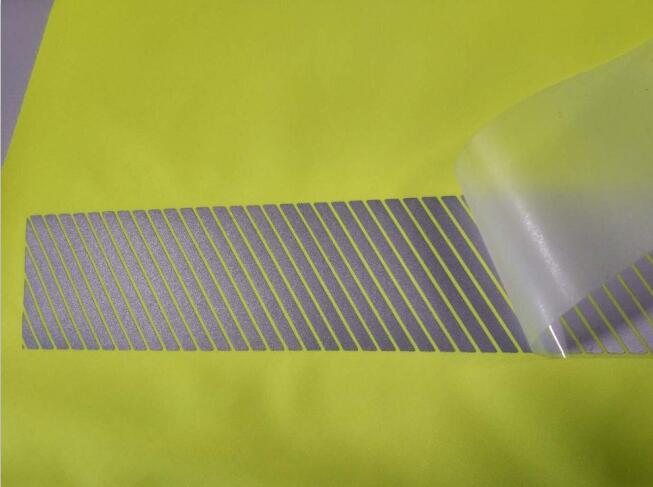

The reflective material for clothing can reflect the direct light from a distance back to the luminous place, and it has a good retro-reflective optical function during day and night. Especially at night, it can display the same high visibility as during the day, allowing people to see from a distance, better Played a warning role.

In recent years, the application of reflective materials has become more and more widespread. The fashion industry has combined the original single-purpose reflective materials with fabrics and applied them to sportswear, school uniforms, work clothes, stage clothes and other clothing, bags, shoes, hats and other items. It can not only highlight the personalized color of the product, but also enhance the safety function of the product. Last time I shared with you the "Fabrication Process of Laser Engraving and Cutting of Thermal Transfer Reflective Film for Clothing Accessories" talked about the production process of thermal transfer reflective film, including the process of engraving and cutting, so everyone knows what this process is Is the equipment made? ——Now almost all of them are made with high-tech products that integrate laser technology, optical technology, precision machinery, electronic technology, computer software technology and refrigeration: laser marking machine. Because the traditional carving film carving machine requires knife pressure, angle, speed and other factors, it is easy to cause product quality problems. However, the laser marking technology is used to mark and cut the carving film, which is ultra-fast, higher precision, and precise computer control The minimum line width can be up to 0.1mm, and the produced lettering film pattern is more delicate and beautiful.

Now, Foshan Fulan Laser will briefly talk about the advantages of using a laser marking and cutting machine to mark, engrave and cut on clothing reflective materials:

1. Layered engraving and cutting, with high precision, smooth and flat cut, generally without subsequent processing;

2. Customizable engraving and cutting any graphics;

3. Material saving: laser processing adopts computer programming, which can cut products of different shapes, maximize the utilization of materials, and greatly reduce the cost of materials for enterprises;

4. The cutting heat affected zone is small, and the deformation of the reflective material is small;

5. The processing accuracy is high and the repeatability is good. The nanosecond laser is used for engraving and cutting processing, which can focus on the ultra-fine space area, while having extremely high peak power and extremely short laser pulses, which will not affect the involved in the processing. The surrounding materials in the space have an impact, thus achieving the "super fine" processing;

6. Non-contact processing, no damage to the surface of the material;

7. Fast processing speed and higher efficiency;

8. Low operating cost: no mold opening, no consumables, fast marking, engraving and cutting speed and one-time forming, low energy consumption, both processing, processing graphics made by software, can change and cut any graphics at any time;

9. Consistent effect: Ensure that the processing effect of different batches of the same product is completely consistent.

The special laser marking and cutting machine for roll materials independently developed and produced by Foshan Fulan Laser Technology Co., Ltd. is specially designed for clothing accessories roll material reflective materials. This equipment can be used for plasters, cloth, stickers, reflective materials, leather, Marking, cutting and perforating plastic film and other roll materials.