Foshan Fulan Laser Technology Co., Ltd.

National Hotline: 0757-29899345

Manager Wen: 18902563402

Fax: 0757-29899345

Business QQ: 2801827697

E-mail: china@fsfulan.com

Address: No.14, Leliu Port Intensive Industrial Zone, Shunde District, Foshan CityThe high-tech zone almond altar town, shunde, foshan city shun industry west road no. 15 cimc valley 20 9 / f, building B

Living in this era of fighting beauty, people are pursuing beauty, and products are also pursuing beauty, starting with beauty, getting stuck in effects, and loyal to quality. The so-called "start with beauty", if a product's beauty is not enough In this homogeneous market with similar configurations and functions, it will soon be buried, and there is no talk of being "trapped in effect" or "loyal to quality".

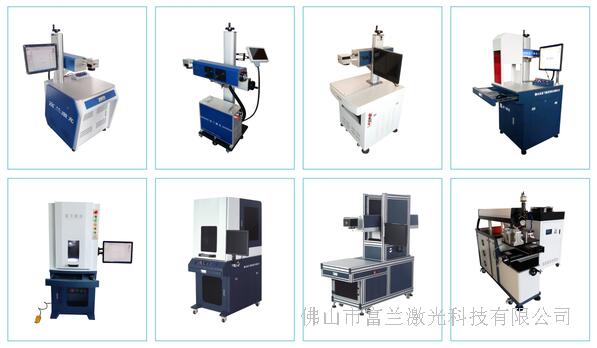

A good appearance is a powerful tool to grab customers' attention. How to improve the product's appearance while ensuring product quality? This is a problem that many companies are thinking about. Fulan Laser tells everyone here: the use of laser technology can solve this problem well, and laser equipment can make the appearance of the product to a higher level. Foshan Fulan Laser Technology Co., Ltd. is an automated laser equipment manufacturer integrating scientific research, production and sales. There are all kinds of laser equipment: laser marking machine, laser welding machine, laser deep engraving machine, laser cutting machine and other laser equipment, as well as automation supporting system. Various non-standard laser equipment can also be tailored according to customer needs.

1. Laser cutting machine

The traditional cutting process has problems such as tool wear, low processing efficiency, and easy to produce burrs, surface roughness, deformation, etc., which can no longer meet the high-quality needs of processing products of various materials. In contrast, the advantages of laser cutting technology have become more prominent and have become the common choice of many processing companies.

The laser cutting machine adopts "non-contact processing", no mold opening is required, and cost saving (laser cutting processing adopts computer programming, which can cut products of different shapes, maximize the utilization of materials, and greatly reduce the company Material cost), thermal deformation is small, processing graphics are made by software, and any graphics can be changed and cut at any time, and the cut is smooth; laser cutting technology effectively improves product quality, reduces production costs, reduces labor intensity, and brings better production to manufacturers benefit.

2. Laser welding machine

The traditional welding process requires mature skilled workers to weld perfectly, with low automation, high defect rate, high cost, slow speed and low precision. The laser welding machine can reduce the heat to the minimum required, the heat affected zone is small, the deformation is small, no electrode is needed, no professional welding technician is required, non-contact welding process, the wear and deformation of the workpiece can be minimized ; The laser welding machine independently developed by Foshan Fulan Laser Technology Co., Ltd. can realize spot welding, butt welding, stitch welding, sealing welding, etc., with high aspect ratio, small weld width, small heat-affected zone, small deformation, and fast welding speed , The welding seam is flat and has no pores, no treatment or simple treatment is required after welding, it can be accurately controlled, the focused light spot is small, the positioning accuracy is high, and it can be equipped with fully automated operation, which greatly improves the welding efficiency and quality. The laser welding is firm, and the weld seam is flat and without pores, which gives the product a solid body and enhances its appearance.

3. Laser marking machine

Laser marking is very common in product circulation, as small as a needle, as large as cars and airplanes, and has a wide range of applications: metal, plastic, wood, leather, stone, glass, cloth, bamboo, etc. For other materials, the laser marking machine can handle all of them. The marks are fine and beautiful, without pollution, and will not fade. While anti-counterfeiting, it also improves the appearance of the product.

4. Laser engraving machine

It uses the thermal energy of the laser to engrave materials, with high efficiency and precise engraving. It can be widely used for engraving various non-metal and metal materials. The surface where the product is carved is smooth and round, which greatly enhances the appearance of the product.