Foshan Fulan Laser Technology Co., Ltd.

National Hotline: 0757-29899345

Manager Wen: 18902563402

Fax: 0757-29899345

Business QQ: 2801827697

E-mail: china@fsfulan.com

Address: No.14, Leliu Port Intensive Industrial Zone, Shunde District, Foshan CityThe high-tech zone almond altar town, shunde, foshan city shun industry west road no. 15 cimc valley 20 9 / f, building B

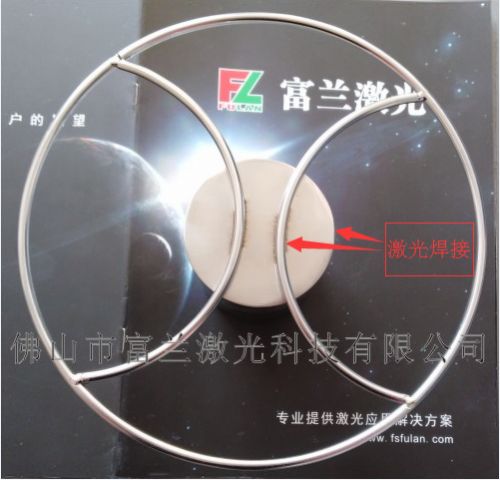

In the leisure time, the sunshine is just right and the breeze is not dry. Organize barbecue activities with friends, colleagues, and family members to enjoy a good time together. It not only allows people to experience the physical and mental relaxation brought by nature outdoors, but also draws closer the feelings between people; or open a barbecue shop, which is also a place that is especially loved by the majority of people... With barbecue in recent years With the increasing rise, the quality of barbecue grills has also attracted attention. The barbecue grills are almost made of stainless steel, because stainless steel is resistant to weak corrosive media such as air, steam, and water, and chemically corrosive media such as acid, alkali, and salt. Corroded steel. The grill will heat up during the barbecue process. If the quality of the grill is not strong, it will cause deformation and even desoldering, which will affect the grilling effect and even cause danger. The traditional welding method has large weld seams and is easy to cause deformation. Polishing and grinding are required after welding; the emergence of laser welding technology perfectly solves the shortcomings of traditional welding.

Let's take a look at the advantages of laser welding machines:

1. High welding seam quality: the products welded by laser welding machine are firm, smooth and beautiful, without pores;

2. Wide range of applications: it can weld all kinds of metal workpieces, and can also join all kinds of heterogeneous materials;

3. Micro-welding can be performed: the laser beam can be focused to obtain a small spot, because it is not affected by the magnetic field and can be accurately positioned, it can be micro-welded;

4. Fast welding speed: the laser beam under computer control can move at high speed, and the welding process can be completed in a few seconds;

5. Strong flexibility: different waveforms can be set to match welding parameters and welding requirements to achieve excellent welding results;

6. Good toughness of the material after welding: laser welding is a welding method, and the toughness of the material after welding is equivalent to that of the parent material;

7. Simple operation: no need for professional welders, ordinary personnel can operate freely after one or two hours of study. The operator only needs to control the computer software to drive the laser welding machine, which can complete automatic or semi-automatic spot welding, butt welding, superposition welding, and sealing welding, as well as welding for complex plane straight lines, arcs and arbitrary tracks;

8. Environmental protection: non-contact coding, no consumables, no pollution, no harmful substances;

9. It can be welded under special conditions: laser welding machine is a non-contact welding machine. Can be welded at room temperature or closed conditions;

10. It is easy to automate high-speed welding, and can also be controlled by digital or computer.

The laser welding machine produced by Foshan Fulan Laser is equipped with a CCD camera monitoring system, which is convenient for observation and precise positioning; it adopts an imported condensing cavity and has a long service life; it can realize automatic laser welding. It is widely used for spot welding, butt welding, stitch welding, sealing welding, tailor welding, seam welding, etc. of stainless steel, aluminum and other metal materials.