Foshan Fulan Laser Technology Co., Ltd.

National Hotline: 0757-29899345

Manager Wen: 18902563402

Fax: 0757-29899345

Business QQ: 2801827697

E-mail: china@fsfulan.com

Address: No.14, Leliu Port Intensive Industrial Zone, Shunde District, Foshan CityThe high-tech zone almond altar town, shunde, foshan city shun industry west road no. 15 cimc valley 20 9 / f, building B

Traditional cutting, printing, grinding, hot stamping, embossing and other methods have been difficult to satisfy the clothing industry. The emergence of laser marking machines and the maturity of processing technology have become a new choice for today's clothing designers. However, the standard laser marking machine has a single function, which is semi-automatic and has lower processing efficiency. The range of marking content is also limited (the maximum range is 300*300mm), etc., which not only causes inconvenience to work, but also affects work efficiency. . Therefore, according to market needs, Foshan Fulan Laser Technology Co., Ltd. independently developed two laser marking machines for clothing fabrics-a full-automatic laser marking and cutting machine for roll materials and a three-dimensional dynamic laser marking machine for denim. .

1. Main features of automatic laser marking and cutting machine equipment for coil materials:

1. The equipment adopts imported laser device, which has the characteristics of small slit, fast speed and high precision;

2. The optical system is composed of multiple imported optical components, high temperature resistance, low loss, fine light spot, uniform light output;

3. The equipment adopts continuous automatic processing method, and the production efficiency is at least twice that of traditional laser processing methods;

4. The automatic loading and unloading, high-precision feeding measurement system is adopted to ensure that the processing graphics are not deformed, and the graphics spacing is always consistent;

5. The transmission system adopts special transmission wheels and imported belts, which are processed by high-precision machinery to make the feeding more stable, and the equipment is smooth, high-speed and non-jittering during operation;

6. There are multiple protections inside the system to ensure that the core components of the system are not damaged under special circumstances;

7. This equipment control system is independently developed by Fulan Laser. The interface can be freely switched between Chinese simplified, Chinese traditional, English, Korean, Japanese and other languages. It supports plt, AI, dxf, bmp, pcx and other file formats, and can automatically Code, print serial number, batch number, date, etc.;

8. This equipment is equipped with a fully enclosed constant temperature cooling system to ensure that the devices in the laser system are dust-proof, clean and constant from the outside world, thereby extending the service life of the laser device and improving the stability of the laser;

9. Marking and cutting can be realized on one product at the same time, and the trimmed edges can be automatically fused without spattering;

10. The whole system adopts one-key switch machine, which is easy to operate.

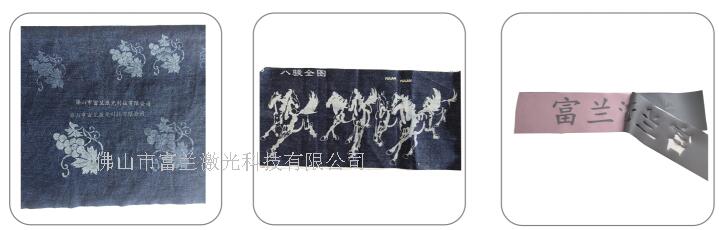

Mainly used for marking, cutting, perforating, burning, engraving, etc. on roll materials such as plasters, clothing fabrics, stickers, reflective materials, leather, etc. For example: marking and cutting of reflective materials, perforating and cutting of ointment stickers, engraving film of materials such as leather and PVC, cutting easy-to-tear thread of various film materials such as PE and PVC, burning denim and so on.

2. Main features of 3D dynamic laser marking machine for denim fabrics:

1. Using radio frequency excitation sealed-off CO2 laser, stable performance, can work for a long time;

2. Using high-speed digital scanning head, small size, fast speed and good stability;

3. The laser power is controlled by software and is continuously adjustable. Marking and cutting can be realized on one product at the same time, and the trimming can be automatically fused, and there is no fraying phenomenon;

4. High engraving and cutting efficiency, environmental protection and energy saving;

5. No consumables, low processing cost;

6. The laser marking machine can not only achieve some traditional monkey, cat whiskers, hole washing and old effects on denim, but also many personalized color discharge printing effects;

7. Stable performance, simple operation, low dependence on manpower;

8. The laser burning pattern can be changed flexibly, the image is clear, the three-dimensional effect is strong, the clear and beautiful, the image is lifelike, the layering is strong, it is durable, not easy to wear, and does not fade.

It is mainly used for burning and cutting denim fabrics. It can also be used for marking and cutting graphics and text in bamboo, wood, leather, cloth, architectural ceramics, clothing accessories, fabric cutting, and rubber product processing.

The advantages of laser processing technology are not only embodied in helping the manufacturing industry to transform processes and achieve upgrading, but it is also the best choice for difficult-to-process manufacturing industries. Especially in the processing of high-strength, high-hardness, low thermal conductivity, and high-brittle materials, the laser uses a high-power laser beam to precisely control the point of action, and outperforms traditional processing technology with advantages such as non-contact processing!