Foshan Fulan Laser Technology Co., Ltd.

National Hotline: 0757-29899345

Manager Wen: 18902563402

Fax: 0757-29899345

Business QQ: 2801827697

E-mail: china@fsfulan.com

Address: No.14, Leliu Port Intensive Industrial Zone, Shunde District, Foshan CityThe high-tech zone almond altar town, shunde, foshan city shun industry west road no. 15 cimc valley 20 9 / f, building B

Two-dimensional codes play an important bearing role for product quality traceability and traceability in industrial production. With the maturity and development of laser technology and the unanimous praise of users, more and more users have started to consult and intend to purchase laser marking machines after they understand the advantages and benefits of laser machines.

Why choose a laser marking machine instead of traditional coding, silk screen and other processes? Next, please come with Fulan Laser to understand the advantages of laser marking machine marking two-dimensional code, you will understand.

1. Adhesion

Laser marking is essentially a kind of "destructive removal" processing. The marked mark is not easy to imitate and change, and the mark will not fade due to environmental factors (touch, acid and alkaline gas, high temperature, low temperature, etc.). Therefore, the mark marked by the laser marking machine is permanent and has a strong anti-counterfeiting property to a certain extent.

2. Clarity

The characters marked by the laser marking machine have extremely high definition. The minimum line width can reach 0.01mm. A 0.06mm character can be seen clearly in every stroke, and the marked two-dimensional code pattern is special Accurate, high and fast scanning rate.

3. Failure rate

The laser marking machine does not require consumables, it can be used immediately after power on, and can work continuously for 24 hours. The failure of the laser marking machine produced by Fulan Laser is almost negligible and basically does not require specialized maintenance personnel. Because the equipment produced by Foshan Fulan Laser Technology Co., Ltd. ranges from the procurement of raw materials to careful installation, from product development, design, production, packaging, transportation to distribution, professional Fulan Laser members strictly monitor every production link, Product quality control, through continuous sampling, testing, tracking and other measures to ensure that the product achieves excellent performance goals.

4. Operating costs

The laser marking machine marks one-time forming, with fast marking speed, low energy consumption, no consumables, maintenance-free, and high degree of automation.

5. Environmental protection:

The laser marking machine is processed by a non-mechanical "light knife", and does not require consumables, does not corrode the working surface, has no "tool" wear, no poison, and no pollution.

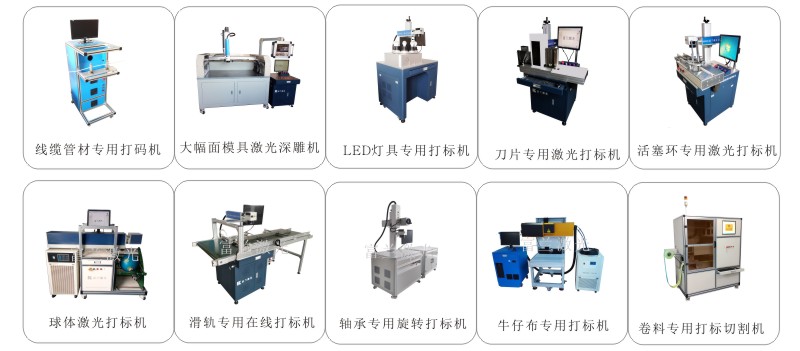

Fulan Laser will serve you wholeheartedly: In response to market needs, Fulan Laser has launched a new series of laser marking machines. The core components of the equipment are independently developed and produced by the Fulan Laser design team. Other main components can be professionally customized according to customer needs. Reliable and stable performance. With automation, rotating tooling, multi-axis and multi-station, CCD visual positioning, automatic focusing and other technologies, combined with the accumulated technology of Fulan Laser for many years, it can provide customers with more advanced, more stable and more efficient solutions. It can also customize a complete set of automatic laser processing solutions for customers to achieve a complete set of automatic laser processing programs, which can reduce production costs to the greatest extent and improve production efficiency.