Foshan Fulan Laser Technology Co., Ltd.

National Hotline: 0757-29899345

Manager Wen: 18902563402

Fax: 0757-29899345

Business QQ: 2801827697

E-mail: china@fsfulan.com

Address: No.14, Leliu Port Intensive Industrial Zone, Shunde District, Foshan CityThe high-tech zone almond altar town, shunde, foshan city shun industry west road no. 15 cimc valley 20 9 / f, building B

With the development of the personalized industry, the pattern of the heat transfer lettering film is particularly trendy. Therefore, thermal transfer lettering film has always occupied a very important market in the apparel industry.

The engraving film is transferred to the clothes in a simple and fashionable way to show a different style, which is the highlight of the contemporary fast-paced characteristics.

Traditional engraving film engraving machine requires knife pressure, angle, speed and other factors that can easily cause product quality problems. However, laser marking technology is used to mark and cut engraving film, which is ultra-fast and precise. The pattern is more refined and beautiful. The laser marking machine can quickly and accurately make various shapes of lettering film in five simple steps:

Step 1: Design the graphics on the computer;

Step 2: Use laser marking and cutting machine for engraving and cutting;

Step 3: Tear off the extra part of the graphic;

Step 4: Place the graphics on the object to be printed for thermal transfer;

Step 5: After cooling, tear off the film on the surface.

--carry out

Now, Foshan Fulan Laser will briefly talk about the advantages of using laser marking machine to make engraving film:

1. Layered engraving and cutting, with high precision, smooth and flat cut, generally without subsequent processing;

2. Customizable engraving and cutting any graphics;

3. Material saving: laser processing adopts computer programming, which can cut products of different shapes, maximize the utilization of materials, and greatly reduce the cost of materials for enterprises;

4. The cutting heat affected zone is small, and the deformation of the reflective material is small;

5. The processing accuracy is high and the repeatability is good. The nanosecond laser is used for engraving and cutting, which can focus on the ultra-fine space area. At the same time, it has extremely high peak power and extremely short laser pulse, which will not affect the involved in the processing. The surrounding materials in the space have an impact, thus achieving the "super fine" processing;

6. Non-contact processing, no damage to the surface of the material;

7. Fast processing speed and higher efficiency;

8. Low operating cost: no mold opening, no consumables, fast marking, engraving and cutting speed and one-time forming, low energy consumption, both processing, processing graphics made by software, can change and cut any graphics at any time;

9. Consistent effect: Ensure that the processing effect of different batches of the same product is completely consistent.

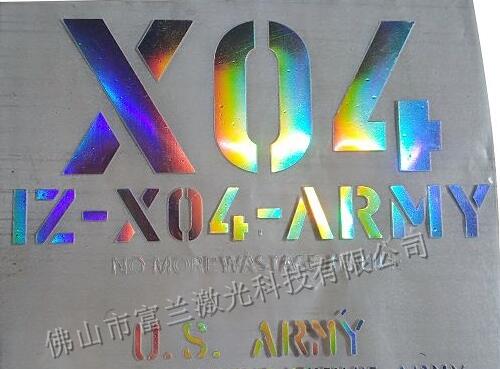

The laser marking and cutting machine produced by Foshan Fulan Laser Technology Co., Ltd. can be used for marking, cutting, and perforating roll materials such as ointment stickers, clothing accessories, stickers, reflective materials, and leather. For example: marking and cutting of reflective materials, perforating and cutting of ointment stickers, marking and cutting of self-adhesives, cutting and easy tearing of various film materials such as PE and PVC, laser marking in industries such as clothing/coats/hats/bags/shoes Label and die cutting (PVC engraving film, TPU engraving film, PU matt engraving film, luminous engraving film, laser soft metal engraving film, reflective engraving film, reflective silk screen film, decorative film, leather label, cloth label, etc. engraving and cutting hollow ).