Foshan Fulan Laser Technology Co., Ltd.

National Hotline: 0757-29899345

Manager Wen: 18902563402

Fax: 0757-29899345

Business QQ: 2801827697

E-mail: china@fsfulan.com

Address: No.14, Leliu Port Intensive Industrial Zone, Shunde District, Foshan CityThe high-tech zone almond altar town, shunde, foshan city shun industry west road no. 15 cimc valley 20 9 / f, building B

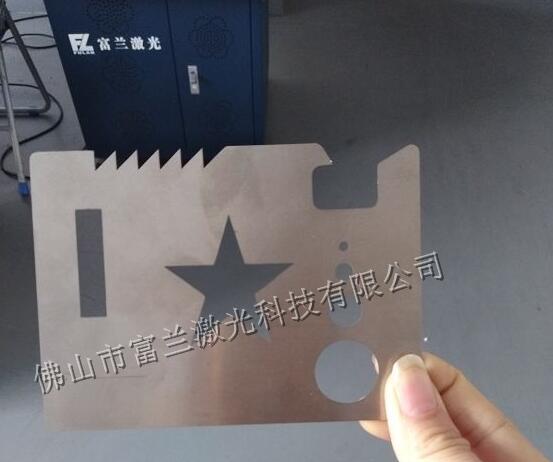

With the development of industry, people have higher and higher requirements for the cutting quality and accuracy of various materials. As a new type of precision cutting tool for thin slices, laser marking machines are gradually being used in all walks of life.

Precision cutting adopts nanosecond or picosecond laser according to the processing object, which can focus on the ultra-fine space area, and at the same time has extremely high peak power and extremely short laser pulse. During the processing, it will not affect the surrounding materials in the involved space. It has the advantages of small cutting seam, smooth cutting surface, beautiful appearance, no need for subsequent processing, fast cutting speed, and high work efficiency. It is especially suitable for production processes that require high precision.

Below, Foshan Fulan Laser will talk about the advantages of laser marking machine in the field of precision cutting of thin sheets:

1. The laser cutting seam is small: the cutting seam is generally 0.1-0.2mm.

2. The laser cutting surface is smooth: there is no burr on the cutting surface, and no treatment or simple treatment is required in the later stage.

3. Small thermal deformation: The laser processing of laser processing has thin slits, fast speed, and concentrated energy, so the heat transferred to the material to be cut is small, and the deformation of the material is also very small.

4. The laser beam is easy to focus and guide, which is convenient for automatic control.

5. Wide range of application: It can be cut on a variety of materials (Note: Because the power of the laser marking machine is low, it is only suitable for precision cutting of thin slices).

6. Safe and reliable: Non-contact processing is adopted, which will not cause mechanical extrusion or mechanical stress to the material.

7. Accurate and meticulous: The minimum line width of the UV laser marking machine produced by Foshan Fulan Laser can reach 0.01mm, and the smallest character can reach 0.06mm.

8. Consistent effect: ensure that the processing effect of different batches of the same product is completely consistent.

9. High speed and fast speed: It can cut at high speed immediately according to the pattern output by the computer.

10. Material saving: The laser cutting process adopts computer programming, which can cut products of different shapes, maximize the utilization rate of materials, and greatly reduce the cost of materials for enterprises.

11. The laser has good spatial control and time control, and has great freedom in the material, shape, size and processing environment of the processing object. It is especially suitable for automatic processing and special surface processing.

12. The laser processing method is flexible: it can meet the production requirements of small batches and also meet the requirements of industrialized mass production. To

13. No consumables, long service life and no pollution.