Foshan Fulan Laser Technology Co., Ltd.

National Hotline: 0757-29899345

Manager Wen: 18902563402

Fax: 0757-29899345

Business QQ: 2801827697

E-mail: china@fsfulan.com

Address: No.14, Leliu Port Intensive Industrial Zone, Shunde District, Foshan CityThe high-tech zone almond altar town, shunde, foshan city shun industry west road no. 15 cimc valley 20 9 / f, building B

Nowadays, many round, ring-shaped, spherical and other products with radian, in order to meet certain requirements or achieve certain effects, a laser marking machine needs to be used to mark around the circumference or a certain arc. . However, the standard laser marking machine does not have the rotation function and cannot meet the marking requirements. Foshan Fulan Laser is customer-centric, thinking about what customers think, what customers worry about, and worry about customers. According to customer needs, it has specially developed and produced several equipment suitable for various arc surfaces-rotating laser marking machine.

Rotary laser marking machine mainly solves the difficult processing requirements of different angles of complex workpieces, and is especially suitable for marking three-dimensional curved surfaces (such as round, cylindrical, arc, sphere, ring and other products). In order to meet the needs of customers at different levels, Foshan Fulan Laser produces rotary laser marking machines that can be divided into 360-degree adjustable rotation of the laser head, 360-degree adjustable rotation of the worktable, and laser head and fixtures. Three kinds of synchronous rotation.

Rotating table: mainly suitable for marking small workpieces. The marking direction can be adjusted by 360 degrees (any arc size) and automatically rotate to mark the workpiece, covering the entire circumferential surface. After setting the relevant parameters, the marking of various surfaces can be completed.

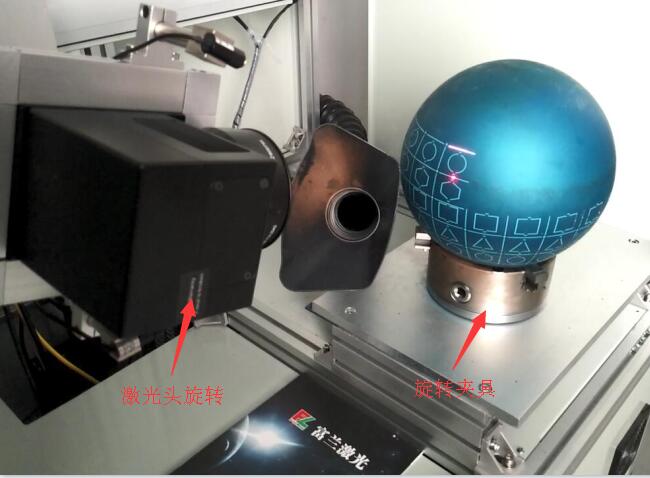

Laser head rotation: It is an independent invention of Foshan Fulan Laser Technology Co., Ltd. and has obtained a patent certificate. Mainly suitable for marking larger or heavier workpieces. By setting the laser marking head on the rotating arm, the laser marking head can be rotated to complete the rotating laser marking process. Compared with the rotating workpiece, it is easier to rotate, and the energy required to rotate the laser marking head is less . The laser head can be adjusted by 360° (any arc size) and automatically rotate to mark the workpiece around the circumference or arc, covering the entire circumferential surface. After setting the relevant parameters, the marking of various surfaces can be completed.

The laser head and the fixture rotate synchronously: It is an independent invention of Foshan Fulan Laser Technology Co., Ltd., and has obtained an invention patent certificate. It is mainly suitable for marking special-shaped and coaxial workpieces. The invention discloses a coaxial curved surface laser processing equipment, including a body. The coaxial curved surface laser processing equipment also includes a laser processing mechanism and a clamping mechanism. The laser processing mechanism includes an adjusting mechanism and a laser. Drive connection to drive the laser to move in the left and right directions, move up and down in the vertical direction and rotate around the left and right axis; the clamping mechanism includes a rotary drive device and a clamping assembly, the clamping assembly includes a clamping table, the clamping table has a rotation axis, and rotates The driving device drives the clamping table to rotate around the rotation axis. By using the coaxial curved laser processing equipment of the present invention to perform laser processing on a specific position of the revolving curved surface, the laser can be flexibly adjusted, adjusted to adapt to the processing surface, and the laser processing effect can be improved.

Foshan Fulan Laser Technology Co., Ltd. has a professional R&D team that can customize non-standard machines for customers and provide more advanced, more stable and more efficient solutions.