Foshan Fulan Laser Technology Co., Ltd.

National Hotline: 0757-29899345

Manager Wen: 18902563402

Fax: 0757-29899345

Business QQ: 2801827697

E-mail: china@fsfulan.com

Address: No.14, Leliu Port Intensive Industrial Zone, Shunde District, Foshan CityThe high-tech zone almond altar town, shunde, foshan city shun industry west road no. 15 cimc valley 20 9 / f, building B

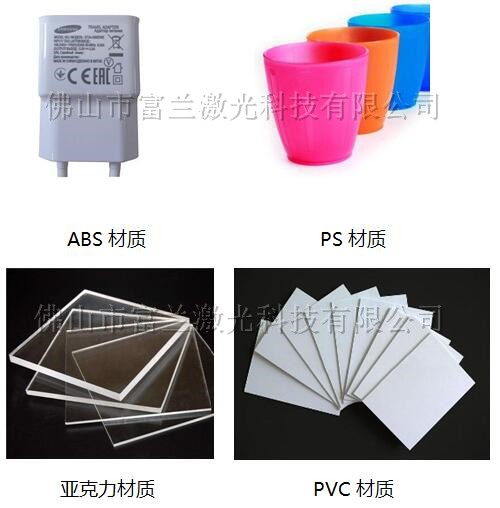

Plastic materials include ABS, PC, PP, PS, PPS, PP, PVC, PE, etc., and these raw materials will be processed in various later stages. To sum up, there are at least thousands of materials. Different types of plastics have different absorption rates of laser energy. Some plastics are easy to absorb laser energy, so it is easy to mark; while some plastics do not absorb laser energy, high-quality marks cannot be made, or even cannot be marked; some are yellowed; some are on the plastic surface during marking. Generate bubbles.

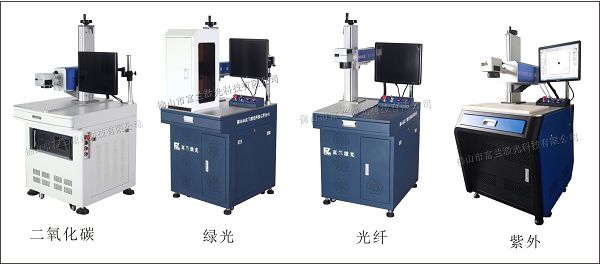

1. What kind of laser marking machine is used for plastic materials?

Optical fiber, green light, ultraviolet, carbon dioxide laser marking machines can all mark on plastics.

1. Optical fiber: suitable for marking some plastic materials with high ignition point (such as: PC, ABS).

2. Green light: Applicable to almost all plastic materials.

3. Carbon dioxide: mainly suitable for acrylic and rubber.

4. Ultraviolet: Suitable for all plastic materials, mainly used in the high-end market of ultra-fine processing. Because the minimum line width of ultraviolet is 0.01mm, and the green light is 0.02mm and other factors, the marking accuracy of ultraviolet laser marking machine is better than that of green light.

Because different types of lasers emit light of different wavelengths. The penetrating ability of different lasers is also different; and the adaptability of different lasers has an impact on the marking quality and marking speed. Therefore, the types of laser marking machines used for plastics of different materials and plastics of the same material and different purity will be different. In addition, each customer has different marking requirements. Therefore, which laser marking machine is the most suitable for your product needs to be proofed before being determined.

Second, the method to solve the blistering and unclear marking on the plastic surface of laser marking

1. The UV laser marking machine is used. Because it has a very small focus spot and a small processing heat-affected zone, it can be used for ultra-fine marking and special material marking. Ultraviolet laser marking machines for particularly sensitive materials and polymer materials are the first choice.

2. Add laser powder to the raw material (also called laser powder, laser additive, laser marking powder). The main function of laser powder is to absorb laser energy, convert the laser beam into heat energy, produce heat, carbonization, evaporation, and chemical reactions caused by the discoloration of additives to the plastic, thereby forming a marking pattern on the surface of the product!

PS: Regarding the blistering phenomenon of some plastic materials in laser marking, the main source is the workpiece. If the marking is performed after the protective oil (that is, the sealing oil), the blistering is unavoidable.

3. Can a variety of different colors be marked on plastic parts?

Can't. Since the laser marking machine is a marking (lettering, engraving) equipment that does not require consumables, the color marked on the object is generally based on the material of the marked workpiece, the model used, and the adjustment Depending on the parameters, it is not what color you want to be able to print out what color.

Fourth, the reasons for uneven marking

1. The energy quality of the laser beam becomes worse.

Solution: Replace the laser with good quality.

2. The level of the machine is not adjusted properly (that is, the vibrating lens or the field lens lens is not parallel to the processing table).

Solution: Place the laser machine steadily and adjust it until the vibrating lens or field lens is parallel to the processing table.

3. The laser output spot is blocked (that is, the spot is not round enough after the laser beam passes through the galvanometer and the field lens): The laser output head, fixing fixture and galvanometer are not adjusted properly, which causes part of the laser spot to be blocked when the laser passes through the galvanometer lens. After the lens is focused, the spot on the frequency doubler is non-circular.

Solution: adjust the machine and fixed fixtures, as well as the position deviation of the galvanometer, and re-adjust.

4. There is a problem with the galvanometer signal, or the galvanometer is interfered by the outside world: the galvanometer jitters slightly during the marking process, so that the marked text or pattern is not clear;

5. The reason for the material of the workpiece to be marked: the uniformity of the material, the uniformity of the texture, the uniformity of the painting or spraying or the thickness of the coating, the inconsistent oxidation time of the oxide parts, etc. will affect the absorption of the laser energy by the material. When the material is not uniform enough When, the effect of laser marking may be uneven.

Solution: The workpiece must be processed before marking.

6. The surface of the workpiece is not on the focal plane.

7. The deflection lens of the galvanometer is damaged: When the laser beam passes through the damaged area of the lens, it cannot be reflected out well, resulting in inconsistent laser energy.

Solution: Replace the damaged field lens and galvanometer lens in time.

8. The marking speed is too fast.

Solution: slow down the marking speed.

9. The service life of the laser is too long, resulting in attenuation.

10. The off-focus marking is used: because each field lens has a corresponding focal depth range, and the off-focus method can easily lead to a large-scale marking pattern, the edge is at the critical point of the focal depth or exceeds the focal depth range , So it is easier to cause uneven effects.

11. The size of the marking content (that is, the processing range) exceeds the scope of the field lens: every laser marking machine will be equipped with a field lens that is limited to a certain range. If the size of the marking content exceeds this range, it will be It is found that the laser effect at the boundary will show an uneven state.

Solution: According to the actual situation of product processing, select the appropriate equipment laser power and the corresponding field lens.

12. The processed products are not placed smoothly, tilted or not parallel to the light path.

Solution: Check whether the machine is placed stably, and check whether the placed product or fixture is tilted.

Five, the color is yellow after marking

Mainly depends on the material itself, the model used and the adjusted parameters, such as PVC plastic, the carbon dioxide laser marking is yellow, oxidation or vaporization color; such as fiber laser marking, it is black; and it is the material itself, laser marking If the parameters of the standard machine are not adjusted correctly, it will cause the output to be yellow.