Foshan Fulan Laser Technology Co., Ltd.

National Hotline: 0757-29899345

Manager Wen: 18902563402

Fax: 0757-29899345

Business QQ: 2801827697

E-mail: china@fsfulan.com

Address: No.14, Leliu Port Intensive Industrial Zone, Shunde District, Foshan CityThe high-tech zone almond altar town, shunde, foshan city shun industry west road no. 15 cimc valley 20 9 / f, building B

Marking or printing a logo on a product has become an indispensable process in industrial manufacturing. There are many kinds of marking equipment, but the most used are laser marking machine and screen printing machine. So, which of the two is better?

Foshan Fulan Laser believes that this depends on what material and product are marked on, each has its own advantages, and the best that meets their needs is the best.

Below, Fulan Laser lists a few items and compares the two.

1. Price:

The price of screen printing is cheaper than that of laser marking machine, but in the later stage, consumables such as ink are often purchased, but laser marking machine has almost no consumables after purchase. Looking at the price of the equipment alone, it is indeed cheaper for silk screen printing. Therefore, many companies first considered reducing costs and chose to purchase silk screen marking equipment. But from the long-term cost of use, does the screen printing equipment really save money?

2. Production cycle:

Silk screen: The cycle is longer and the process is more complicated. It usually takes a week.

Laser marking: The cycle is very short, marking as soon as you need it, the process is simple, and the flexibility is strong.

3. Environmental protection:

Silk screen: Environmental pollution is high. Silk screen printing needs ink, but ink is the biggest source of pollution in the printing industry. Because it is an organic volatile matter, it will form oxides and photochemical fumes under sunlight, and the smell is particularly strong and pungent. Long-term operation may affect people's health.

Laser marking: Laser processing uses the focused light spot, no additional equipment and materials are needed, non-contact coding, no pollution, no harmful substances, and can pass through drug-resistant water, abrasion resistance, and high temperature resistance. test.

4. Flexibility:

Silk screen: It can only be used for relatively flat products, if there are some irregularities, it can't be solved completely.

Laser marking: It can be marked on flat, round and irregular surfaces, and the effect is particularly good.

5. Processing efficiency:

Silk screen: There are many processes, and each link requires manual operation. After use, cleaning up is still very troublesome.

Laser marking: All marking information is edited by computer in real time, and any information can be marked, without the need to open a mold and make a plate. No matter it is text, serial number, LOGO, certification symbol, QR code, etc., as long as the artwork marking system designed in the computer can recognize it, the marking machine can accurately restore the design information on a suitable carrier. It can also be configured in assembly line production, and can also realize fully automatic marking, without manual operation, and can work continuously for 24 hours, which is convenient and fast.

6. Scope of application:

Silk screen: A screen is almost only suitable for one product, because its content and size are fixed.

Laser marking: One machine is suitable for marking products with multiple materials, and the content can be edited and modified at will.

7. Marking accuracy:

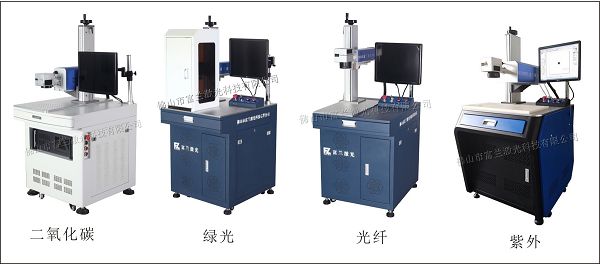

The minimum line width of the UV laser marking machine produced by Foshan Fulan Laser can reach 0.01mm, which is several times more accurate than silk screen printing.

8. Identification color

Screen printing requires ink consumables, the color can be selected, and almost any color can be printed;

The color engraved by the laser marking machine is relatively single, and it is almost impossible to choose one. Generally, it is white or black or brown. Since the laser marking machine is a marking (lettering, engraving) equipment that does not require consumables, the color marked on the object is generally based on the material of the marked workpiece, the model used, and the adjustment Depends on the parameters.

Through the above comparison, it is not difficult to see that the laser marking machine is superior in terms of operating environment, efficiency, cost, and processing methods.