Foshan Fulan Laser Technology Co., Ltd.

National Hotline: 0757-29899345

Manager Wen: 18902563402

Fax: 0757-29899345

Business QQ: 2801827697

E-mail: china@fsfulan.com

Address: No.14, Leliu Port Intensive Industrial Zone, Shunde District, Foshan CityThe high-tech zone almond altar town, shunde, foshan city shun industry west road no. 15 cimc valley 20 9 / f, building B

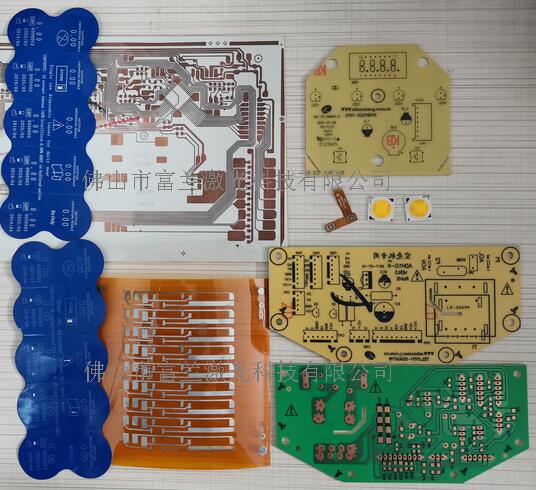

As an important component and circuit connection carrier in the 3C industry, PCB circuit boards have become more intelligent with the development of the electronics industry, and there are more and more electronic components, and the requirements for precision processing are getting higher and higher. Because the traditional silk screen processing has too many shortcomings (such as: 1. The logo of the silk screen is rough, easy to fade, and easy to fall off, which causes inconvenience to the user; 2. The processing procedure is cumbersome and requires the operator to replace it in time to ensure production efficiency and increase labor. Cost; 3. Ink is a kind of chemical material, long-term contact is harmful to the human body, and the pollution to the environment is also great, etc.), so now industrial parks in many areas do not allow silk screen printing.

There are many ways to mark PCB circuit boards. Except silk screen printing is not available, laser marking is the best choice. Moreover, the laser marking machine has high marking accuracy, fast speed and stable performance. It only needs to be controlled by a computer, and the operation is simple. It can mark various complicated patterns, texts, two-dimensional codes and other content, which meets the high-quality marking requirements of the existing PCB industry. . Therefore, most circuit board manufacturers now choose laser marking machines for processing.

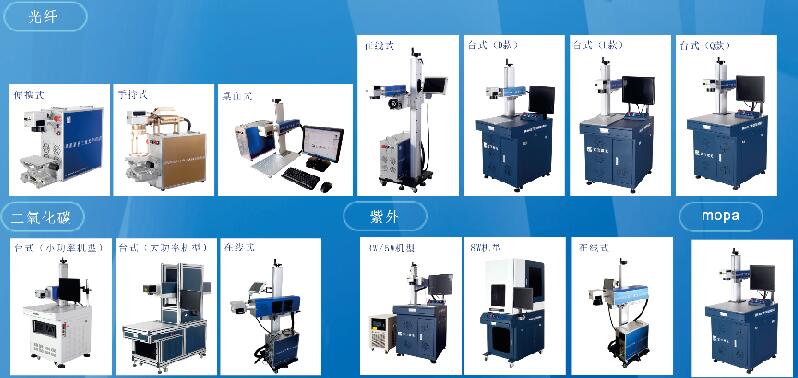

Next, Foshan Fulan Laser Technology Co.,Ltd. will introduce to you what advantages the online laser coding machine has on the PCB board:

1. The mark is permanent: the mark engraved by laser is not easy to imitate and change, and it will not fade due to environmental relations (touch, acid and alkaline gas, high temperature, low temperature, etc.).

2. High precision: the graphics and texts marked by the laser marking machine are beautiful, delicate, fine and clear, and the minimum line width can reach 0.01mm, which can meet the needs of engraving large amounts of data on extremely small workpieces.

3. High processing efficiency: The laser marking machine is controlled by an industrial computer. The laser beam under computer control can move at a high speed, and the marking process can be completed within a few seconds.

4. Fast editing and development speed: processing as needed, marking any content and editing at will.

5. Consistent effect: Ensure that the processing effect of different batches of the same product is completely consistent.

6. High flexibility: it can meet the needs of commercial small batch or single processing, and can also be configured in the assembly line to achieve online flying laser marking to meet the needs of fast assembly line mass production.

7. Support automatic coding, print serial number, batch number, date, barcode, two-dimensional code, etc. will automatically skip the number.

8. Non-contact processing: the workpiece will not produce internal stress after marking, ensuring the original accuracy of the workpiece. There is no corrosion on the surface of the workpiece, no "tool" wear, no poison, no pollution.

9. Environmental protection: no consumables, no harmful substances to the environment and human body, no pollution, in line with GB7247-87; GB10320-88 standards. However, some materials will produce smoke when laser marking, generally use the smoke exhaust system to deal with. Compared with the corrosion method, chemical pollution is avoided; compared with mechanical marking, noise pollution can also be reduced.

10. Simple operation: No experience is required. Foshan Fulan Laser will conduct professional one-on-one training operations for customers until the customer's operators can operate the equipment correctly and skillfully, which can generally be learned within 2 hours.

11. High degree of automation: using computer integrated intelligent operation, it can realize automatic feeding, automatic identification and positioning, automatic marking, etc., the marking speed is super fast; it can work in static and high-speed flow state of the production line.

12. Stable performance: It can work continuously 24 hours a day, 7 days a week. The maintenance-free time is more than 20,000 hours.

13. Low failure rate: The equipment produced by Foshan Fulan Laser Technology Co., Ltd. ranges from the procurement of raw materials to careful installation, from product development, design, production, packaging, transportation to distribution, and Fulan Laser strictly controls the quality of products and passes Continuous sampling, testing, tracking and other measures ensure that the product achieves excellent performance goals. The failure of the laser marking machine produced is almost negligible, and there is basically no need for specialized maintenance personnel.

It can be seen from the above that the effect of using a laser marking machine on a PCB circuit board is significantly better than that of the traditional marking method. The non-contact processing can ensure that there are no accidents during the processing process, and the effect is smooth and fine.

The laser coding machine cooperates with automation, multi-axis and multi-station, CCD vision positioning, automatic focusing and other technologies, and integrates the accumulation of years of Fulan laser technology, which can provide customers with more advanced, more stable and more efficient solutions. It can also customize a complete set of automatic laser processing solutions for customers to achieve a complete set of automatic laser processing programs, which can reduce production costs to the greatest extent and improve production efficiency.