Foshan Fulan Laser Technology Co., Ltd.

National Hotline: 0757-29899345

Manager Wen: 18902563402

Fax: 0757-29899345

Business QQ: 2801827697

E-mail: china@fsfulan.com

Address: No.14, Leliu Port Intensive Industrial Zone, Shunde District, Foshan CityThe high-tech zone almond altar town, shunde, foshan city shun industry west road no. 15 cimc valley 20 9 / f, building B

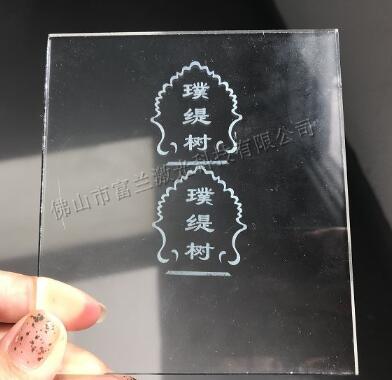

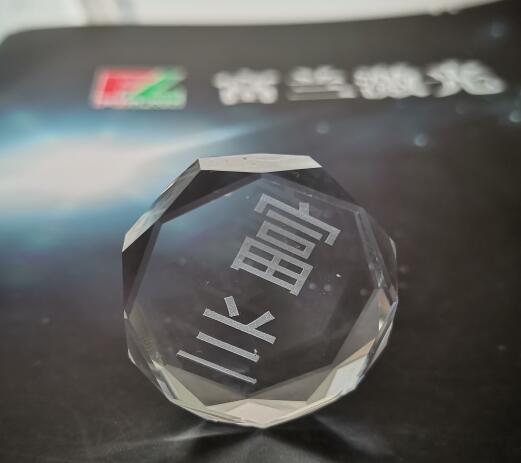

The ultraviolet laser marking machine produced by Foshan Fulan Laser can engrave flat or three-dimensional patterns in transparent materials such as crystal and glass (the so-called laser engraving). Laser internal engraving technology is currently an advanced and popular engraving method in the world. It can be widely used in the production of glass handicrafts, souvenirs and fine engraving of internal and surface patterns of decorative glass. The craftsmanship of various crystals, glass and other transparent objects has The crystal clear, otherworldly visual image, immersed in the noble and elegant artistic charm.

Laser internal engraving refers to the laser machine injecting a certain wavelength of laser into the material, and the spatial position of the burst point in the glass body is controlled by a calculator, so that a specific part of the material inside the material produces a micron-sized vaporized burst point to form bubbles, thereby delineating It is a kind of processing technology to produce a preset shape.

The principle of laser engraving: mainly used in light interference phenomenon. The laser internal engraving marking machine shoots two laser beams into transparent objects (such as glass, crystal, etc.) from different angles, and they meet exactly at one point. Because the two laser beams interfere and cancel at the intersection point, their energy is converted from light energy to internal energy, releasing a lot of heat, melting the point to form a tiny cavity. The machine accurately controls the intersection of the two lasers at different positions to create a large number of tiny cavities, and finally these cavities form a predetermined shape, while the rest of the glass or crystal remains intact. This is the principle of laser engraving.

The UV laser marking machine produced by Foshan Fulan Laser Technology Co., Ltd. has a wavelength of 355nm UV laser output. After focusing, the spot diameter is smaller, the energy is more concentrated, the electro-optical conversion efficiency is high, stable power output, and superior beam quality. Make the marking super fine, higher definition; cold light source, small heat affected area. The wide range of applicable materials makes up for the problem that many materials are not well marked with other types of laser marking machines and the effect is not good. It is mainly used in the high-end market of ultra-fine processing, marking of high-molecular material packaging bottles; metal or non-metal coating removal; scribing of various materials, blind groove processing; new ultra-thin metal foil micro-hole production, etc. It can also be used for surface carving and internal carving of glass products and crystal products.

Glass product packaging bottle laser engraving production date batch number (automatically skipped): make the product more high-end

Glass carving pattern: ordinary glass becomes refined in seconds

Crystal laser engraving