Foshan Fulan Laser Technology Co., Ltd.

National Hotline: 0757-29899345

Manager Wen: 18902563402

Fax: 0757-29899345

Business QQ: 2801827697

E-mail: china@fsfulan.com

Address: No.14, Leliu Port Intensive Industrial Zone, Shunde District, Foshan CityThe high-tech zone almond altar town, shunde, foshan city shun industry west road no. 15 cimc valley 20 9 / f, building B

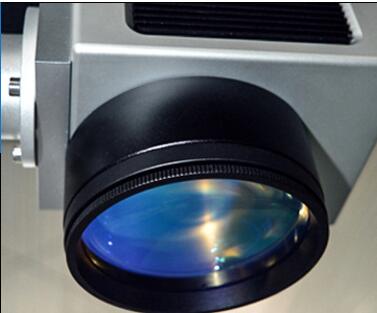

Field lens, also called plan focusing lens, f-theta focusing lens, is a professional lens system and one of the most important parts of laser marking machine. The purpose of the field lens is to form a uniformly sized focused spot of the laser beam in the entire marking plane, and change the position of the imaging beam without changing the optical characteristics of the optical system. Simply put, it determines the laser working range of the laser marking machine.

The main function of the field lens:

1. Improve the ability of the edge beam to enter the detector;

2. In the same main optical system, the additional field lens will reduce the area of the detector; if the same area of the detector is used, the field of view can be enlarged and the incident flux can be increased;

3. The non-uniform illumination on the photosensitive surface of the detector can be homogenized.

The main technical parameters of the field lens:

When selecting a field lens, the main technical parameters considered are working wavelength, entrance pupil, scanning range and focusing spot diameter.

Laser wavelength: The field lens is coated at a given laser wavelength. If the field lens is not used within the given wavelength range, the field lens will be burnt out by the laser.

Entrance pupil: If a single lens is used, the reflector is placed at the entrance pupil, and the diameter of the maximum usable beam is equal to the diameter of the entrance pupil.

Scanning range: Foshan Fulan Laser often uses field lenses in several ranges of 70*70/ 110*110/ 170*170/ 220*220/ 300*300mm.

Focusing spot diameter: A smaller focusing spot can be obtained with a beam expander.

The size of the field lens corresponds to the size of the laser power. When the laser power is constant, the increase of the scene causes the energy of the laser to irradiate the surface of the object to be correspondingly weakened, thereby affecting the processing accuracy and quality. Therefore, in order to ensure the marking effect, Fulan Laser recommends that when purchasing a laser marking machine, you should not blindly pursue a large range of scenes, but should choose appropriate equipment and matching field mirrors according to the actual processing conditions of the product.

Matters needing attention during field lens maintenance:

The laser is emitted from the laser head through the reflection and focusing of the lens. During the process, the lens is easy to be stained with fine dust, which causes the loss of the laser or the marking effect is not good. At this time, proper wiping and maintenance are required. Pay attention to the following points when wiping and maintaining:

1. The lens should be wiped gently, and the surface coating should not be damaged to prevent it from falling;

2. When installing the focusing lens, be sure to keep the concave surface down;

3. For lens cleaning, please use tweezers, finger cots, and rubber gloves to take the lens;

4. The lens should be placed on the lens paper to avoid damage (do not put the lens on a hard or rough surface, the lens is easily scratched);

5. Use an air ball to blow off the floats on the surface of the lens. Note: Do not use compressed air from the factory because it contains a lot of oil and water, which will form a harmful absorption film on the surface of the film.